STATE OF THE ART

Aerospace & Defense Contract Manufacturing

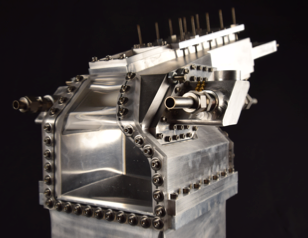

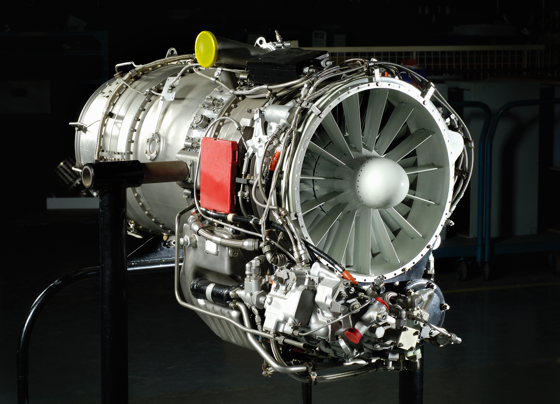

Starwin Industries is dedicated to creating top-tier, innovative solutions for intricate challenges across diverse industries, impacting the world through advanced manufacturing capabilities. By leveraging cutting-edge technology and a highly skilled engineering team, we provide our customers with comprehensive manufacturing services including complex assemblies, prototyping, and manufacturing engineering, catering to a wide range of needs, from aircraft components and spaceflight hardware to custom projects. Our extensive experience spanning over 50 years showcases Starwin's ability to deliver high-quality solutions for even the most demanding applications.

Our Capabilities

DISCOVER

Our Specialties

While we employ the value of the latest tools and machinery, we firmly believe that the talent and experience of the Starwin team is what truly enables us to accomplish anything. Our unrivaled expertise in composite manufacturing and complex assemblies dates back to the founding of Starwin Industries in 1964 and is demonstrated within all of our historic accomplishments since then. We understand the importance of uncompromised quality and reliability as a result of serving notable customers such as Department of Defense, Lockheed, Raytheon and GE, and our unique experiences offer our customers valuable perspective within each of their projects. Explore our specialties: