Manufacturing

Prototyping

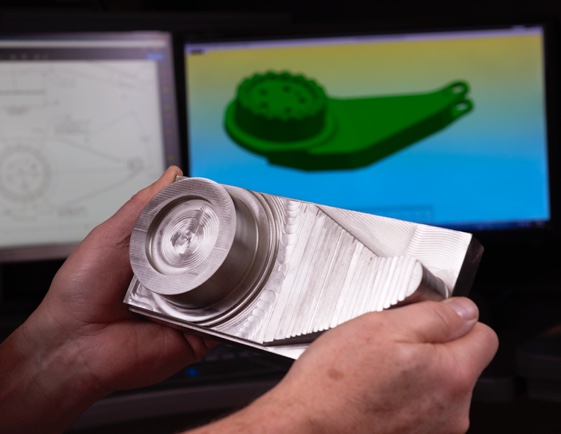

At Starwin Industries, we understand the pivotal role prototyping plays in successfully transforming visions into realities. From complex one-off components to scale models like our Lunar Lander and Command Module, there are no limits. We also realize the necessity of support solutions for legacy components, for which we utilize high-caliber reverse engineering and life cycle management. Our aerospace and defense clients, like NASA and the US Military, must plan for everything, and they trust us because we do the same.

Low to High

Volume Manufacturing

While the processing requirements to produce prototypes vs. production runs can vary, we do not believe they are mutually exclusive. This is important because when quality and schedule are of the utmost importance, the components must be on-time and you only get one chance to get them right. We know this because we experienced it first hand in our involvement on the Lockheed Joint Strike Fighter, on which we were named a preferred supplier for the project. With attention to quality verification, we can reduce the risk of costly errors through developing robust processes for either low or high volume production requirements. Additionally, our expertise includes 3, 4, 5 axes and 3D precision machining, as well as material varieties including: metals such as aluminum, magnesium, cast iron, steel, titanium and high-temperature exotics; and fiberglass, carbon fiber, Kevlar, plastics, and wood.

Reverse Engineering

& Life Cycle Management

The absence of a replacement part can halt your productivity or critical mission. Whether your replacement part has become unavailable by the manufacturer, or the part data no longer exists, Starwin Industries can provide a solution. We have the ability to reverse engineer and manufacture new parts from an existing part when data is not available. This capability is also advantageous in component life cycle management for creating efficiency in outdated processes. For legacy military systems that are limited to decades old replacement parts, we can redevelop and optimize efficiency in both the part and production process, ultimately extending the life of these valuable systems.