Complex Assemblies

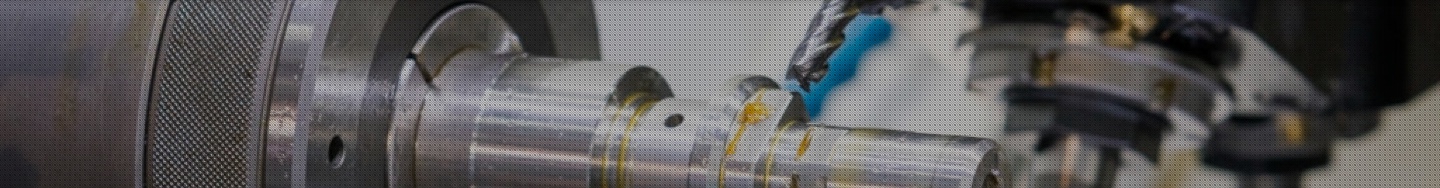

Put simply, we engineer and manufacture solutions for complex problems. To achieve this, we recognize that complex assemblies are equal parts delicate artistry and scientific discipline – and we masterfully incorporate both on every project we undertake whether in the aerospace and defense industries or beyond. Our commitment to leading the cutting-edge of machining capability enables us to manufacture virtually any complex assembly, including test rigs and machine components, but the seasoned craftsmanship of our team is what delivers the quality value that has earned us the trust of the fastidious industries we serve.

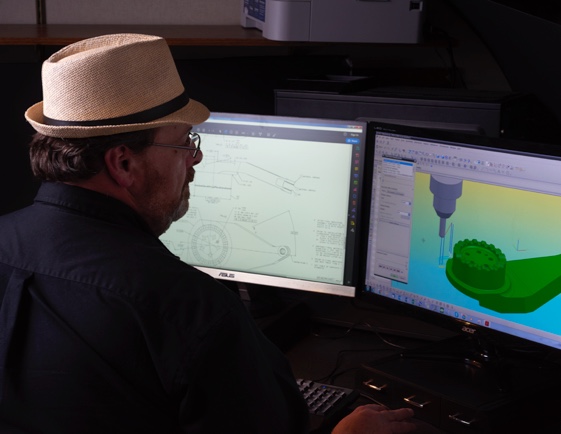

Advanced Engineering &

Precision Machining

With over 50 years of industry experience, we’ve honed and perfected our engineering process. Specifically, with industry-leading Unigraphics CAD/CAM software, we can accept electronic data in virtually any file format including native Unigraphics files, Parasolid, IGES, STP and several drawing formats to provide flexibility and zero interpretation errors. Our 3D 5-axis machining and bonding expertise deliver precise and reliable construction regardless of material combination. Further, our comprehensive quality management system ensures your complex assembly is nothing short of the best before the final product leaves our facility.

Individualized

Product Production

In serving the specialty requirements of our customers over the years, such as the Turbulence Control Structure (TCS dome) for GE, we bring unique perspective and advantageous experience to the evolution of your complex assembly. At Starwin Industries, we assign each complex assembly project to a dedicated project manager to oversee the entire process from start to finish – utilizing Microsoft Project software to ensure optimal organization in every logistical aspect. In addition to precise progress tracking, our experts masterfully handle resource allocation and budget management. Through our strong vendor partnerships, they’re able to recommend the highest quality and cost-effective materials from our network of trusted suppliers.