Precision Crafted

Machine Components

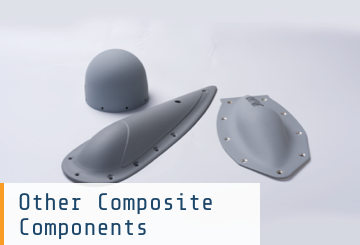

While the industries we serve have vastly different requirements when it comes to machine components, Starwin is no stranger to a challenge. From our involvement in the applied engineering of Lockheed’s Joint Strike Fighter or NASA’s prototype rocket nozzles, one thing holds true for each of our clients – they share the same expectations: expertise, timely delivery, and single-shot precision. Our 50+ year track record, and the honor of being a preferred supplier to NASA and the US military, demonstrate Starwin’s ability to deliver.

Machine Components for

Aerospace & Defense

When designing hardware that will either be flying through our atmosphere – or leaving it entirely – the specs are absolute, and second chances are never an option. This is why Starwin specializes in close tolerance machining, as well as low-volume processing when needed, to ensure ultimate accuracy, precision in performance, and an efficient, tailored manufacturing process that is best suited to the project. Our expertise in traditional and exotic materials includes aluminum, magnesium, cast iron, tool steel, titanium, stainless steel, and high temperature alloys like Waspaoly, Iconel, and Hastelloy, in addition to plastics and FRP composites like fiberglass, carbon fiber, and Kevlar. Current technologies in machining and data handling allow us to expand our capabilities, but we believe craftsmanship and personal commitment are required for a quality product.

Contact

Starwin Industries

Have a question about one of our specialized products or need a custom engineered solution?

Contact us! We’re here to help!